|

|

-

-

LABORATORY STIRRED REACTORS

|

|

|

-

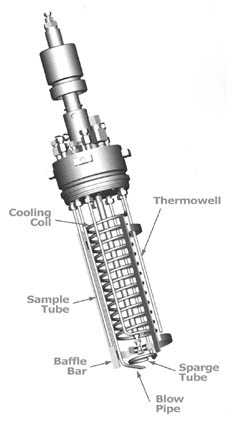

PRESSURE VESSEL

-

M.A.W.P :

- Up to 5,800psig @ 650°C

- Max(400bar @ 343°C)

-

SIZE :

- 50ml

- 100ml

- 300ml

- 500ml

- 1,000ml

- 2,000ml

- 4,000ml

- Others

-

SEAL MATERIALS :

- Metal Gasket (350°C)

- Buna N (70°C)

- EPDM (150°C)

- PTFE (230°C)

- Viton (200°C)

- Silicon (200°C)

- Kalrez (260°C)

-

INTERCHANGEABLE VESSEL SIZE :

- - 100ml <-> 300ml

- - 500ml <-> 1,000ml

- - 2,000ml <-> 4,000ml

|

|

|

|

|

100ml

|

300ml

|

500ml

|

1,000ml

|

2,000ml

|

4,000ml

|

|

Inside Diameter

|

46mm

|

46mm

|

76mm

|

76mm

|

127mm

|

127mm

|

|

Inside Length

|

70mm

|

190mm

|

116mm

|

221mm

|

160mm

|

320mm

|

Special Dimension도 가능합니다.

Note :

MAWP는 Metal Seal을 기준으로 한 것이며 Seal Material에 따라 Pressure Rating과 Temperature가 결정됩니다.

|

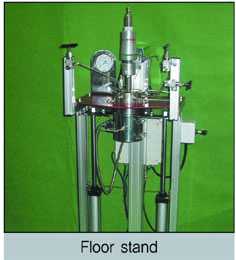

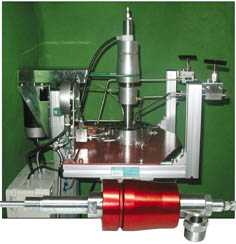

STAND TYPE

|

|

|

|

-

- Aluminum Profile을 이용하여 견고하게 제작되었으며 Open형이라 쉽게 작업 할 수 있습니다.

-

- Vessel의 Volume에 따라 두가지 type의 Stand Model이 있습니다.

|

|

STYLE

|

50,100 & 300ml

|

500 & 1,000ml

|

2,000 & 4,000ml

|

Wide

|

Deep

|

Tall

|

|

Bench Top Stand

|

O

|

|

|

380m

|

400m

|

960m

|

|

Floor Stand

|

|

O

|

O

|

560m

|

650m

|

1550m

|

-

AGITATION

|

|

-

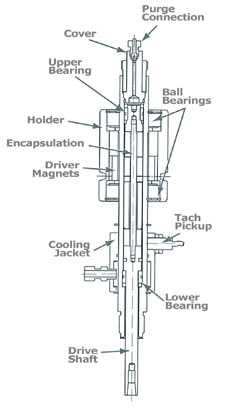

MAGNETIC DRIVE

- - 고속, 고압, 고온에서 Mechanical Seal보다 탁월한 안정성과 성능을 보입니다.

- 특히 고압에서(Up To 500bar) 전혀 Leakage가 없으며 안전하게 사용 가능

- 합니다.

- - Mechanical Seal 보다는 Mixing Torque가 약한 단점이 있습니다.

- - Pressure Rating : Up To 500bar

- - Temperature Rating : 500°C

- - Material : 316ss, HC -276, ...etc

- - Static Mixing Torque : 10in-lbs ~ 500in-lbs

- - Connection Seal : 0 - Ring, PTFE, Metal Seal

|

Note :

Magnet(Neodium)은 90°C 아래에서 안정적입니다.

90°C 이상을 초과하게되면 자력이 떨어져 결과적으로 Mixing Torque를 떨어뜨립니다.

이러한 문제를 막기위해 Cooling Jacket을 부착하여 Vessel의 온도가 Magnet에 전달되는 것을 차단합니다.

|

-

BEARING MATERIAL

- Chemical에서 내식성,내화학성이 우수한 Bearing 재료인 Carbon Teflon을

- 사용하여 Mixing의 안전성과 내구성을 높였습니다.

|

|

-

SPEED SENSOR

- Magnetic Drive의 특성상 외부 Rotor가 회전해도 내부 Rotor가 회전하지

- 않아서 Mixing이 안되는 경우가 있습니다.

- 육안으로 보이지 않기 때문에 Hall Effect Sensor를 이용하여 내부 Motor의

- 회전을 감지하여 Digitial RPM을 표시합니다.

|

-

MOTOR

- Magnetic Drive와의 연결은 Belt Driven Type이나 inline Type으로 연결됩니다.

- Motor는 Standard로서 D.C. Motor (180VDC 비방폭)가 적용되고 Option 으로는

- A.C Motor (방폭 D2G4), D.C. Motor (방폭 D2G4), 또는 Air Motor를 장착하기도

- 합니다.

|

| 500 ~ 1,000ml : 1/4HP |

| 2,000 ~ 4,000ml : 1/2HP |

|

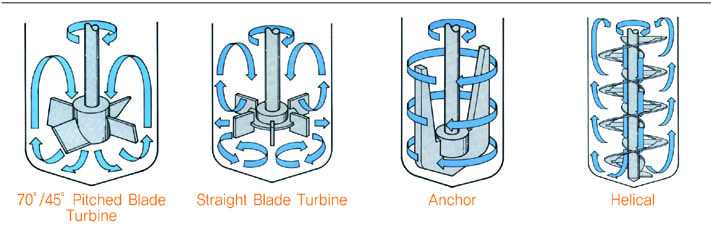

- IMPELLER

|

Standard로는 70° Pitched Blade Turbine Impeller가 제공되며 Customer의 실험목적에 따라서 다양한 모양의 Impeller를

선택할 수 있습니다.

|

|

| Impeller Diameter (Except Anchor & Helical Impeller) |

| 100 - 300ml : 25mm |

500 - 1,000ml : 35mm |

2,000 - 4,000ml : 55mm |

|

|

|

-

INTERNAL ACCESSORIES

|

|

-

LIQUID SAMPLE

- Liquid Sample Tube를 통해 반응 중에 Liquid를 Sampling 할 수 있습니다.

|

-

BLOW PIPE

- Reactor에 Drain Valve가 장착되지 않은 경우 모든 Liquid를 제거하기 위해

- 쓰입니다.

- Vessel Bottom의 Solid를 제거하는 목적으로도 쓰입니다.

|

- Liquid 수위 아래에서 Gas를 Injection하기 위해 쓰입니다.

|

- Cooling Coil은 내부 Reactor의 반응물을 냉각시키는 목적으로 사용되고

- Standard로는 내부에 장착되며, Cooling의 제어는 Standard로 220VAC

- Solenoid Valve가 장착됩니다.

|

- Thermocouple을 이용하여 Reactor의 반응물의 온도를 실시간으로

- 측정할 수 있도록 해줍니다.

- Thermocouple로는 "K" Type이 쓰입니다.

|

|

|

| Internal Tube Size (Sampling/Blow Pipe, Sparge Tube, Cooling Coil, Thermowell ) |

| 100 - 300ml : 1/8" |

500 - 1,000ml : 3/16" |

2,000 - 4,000ml : 1/4" |

|

-

EXTERNAL ACCESSORIES

-

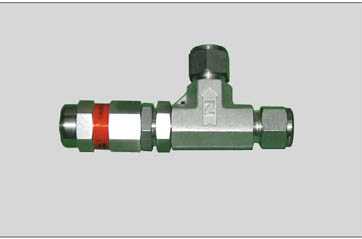

PROCESS VALVES

-

Standard로 Vent Valve/Sampling Valve가 부착됩니다. 필요에 따라 여러개의 Valve가 장착되어 집니다.

|

-

PRESSURE GAUGE / TRANSDUCER

|

|

- Standard로 100mm Dia, Pressure Gauge가 부착 됩니다.

- Gauge Type은 Use No Oil Type이 선정되어 Gas의 오염과

- 폭발 위험을 막을 수 있습니다.

- Option으로 Transducer가 장착되면 압력을 Digital로 읽을

- 수 있습니다.

|

-

SAFETY DEVICE

-

Standard로 Rupture Disc가 장착되며 필요에 따라 Relief Valve가 장착되기도 합니다.

Over Pressure가 발생할 경우 System과 계측기 보호를 위해서 작동되어 System을 안정화 시킵니다.

|

|

|

-

HEATING

-

Standard로 Electric Ceramic

Heater(220VAC)를 사용하며

필요에 따라서는 Removable

External Heating Jacket이

부착됩니다.

|

|

|

| Eletric Ceramic Heater Capacity |

| 50 - 100ml : 500Watts |

300ml : 1KW |

500ml : 1.5KW |

| 1,000ml : 1.7KW |

2,000ml : 2.5KW |

4,000ml : 4KW |

|

|

-

OTHER ACCESSORIES

- - Gas, Liquid Feed Control System : MFC, MFM,

- Micro Meteny Pump, Product Handling System

- - Data Acquisition System : Process Automation

- - Level Control System : Catalytic System

|

|

-

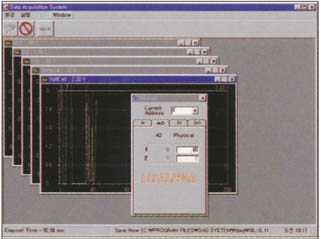

DATA ACQUISITION / CONTROL(Option)

- - Reactor에서 들어오는 모든 Signal을 Computer에서 받아서

- 저장 및 Control할 수 있습니다.

- - Auto Data Save & Manager

- - Zero-Span Available

- - Edit Control Loop

- - Graphic Monitoring

- - Sampling Time Adjustable

|

MODULAR CONTROL SYSTEM

Modular Control System은 연구소나 산업현장에서 많이 쓰이는 기기중 하나이며, Customer의 다양한 요구에 부합하여

Controller를 제작하고 있습니다.

주로 Temperature, Speed, Pressure, Flow Level을 Control하며 그 외에도 다양한 Option이 있습니다.

|

|

- - Complete Temp, Speed, Pressure, Level, Flow, Power Control System

- - Temperature : PID-Auto Tuning, Programming, Heating & Cooling Mode

- - Speed : Manual or Automatic adjust

|

|

- - Digital Pressure Indication or

Control

- - Digital Level Indication or Control

- - Digital Flow Indication or Control

- - Remote Shutdown

- - Suitable for 19" Rack Mounting

- - Separate On/Off Switch for

Instrument

- - Over Current Protection Fuse

- - Pin Connector on the Rear Panel

|

-

OPTION

- - Program Control (Temperature, etc)

- - Automatic Control (Speed, Pressure, etc)

- - Recorder

- - Data Acquisition & Control

- - Ampere / Volt Meter

- - Event Output

- - Explosion Proof

|

|

|